CNC Update #1

Share

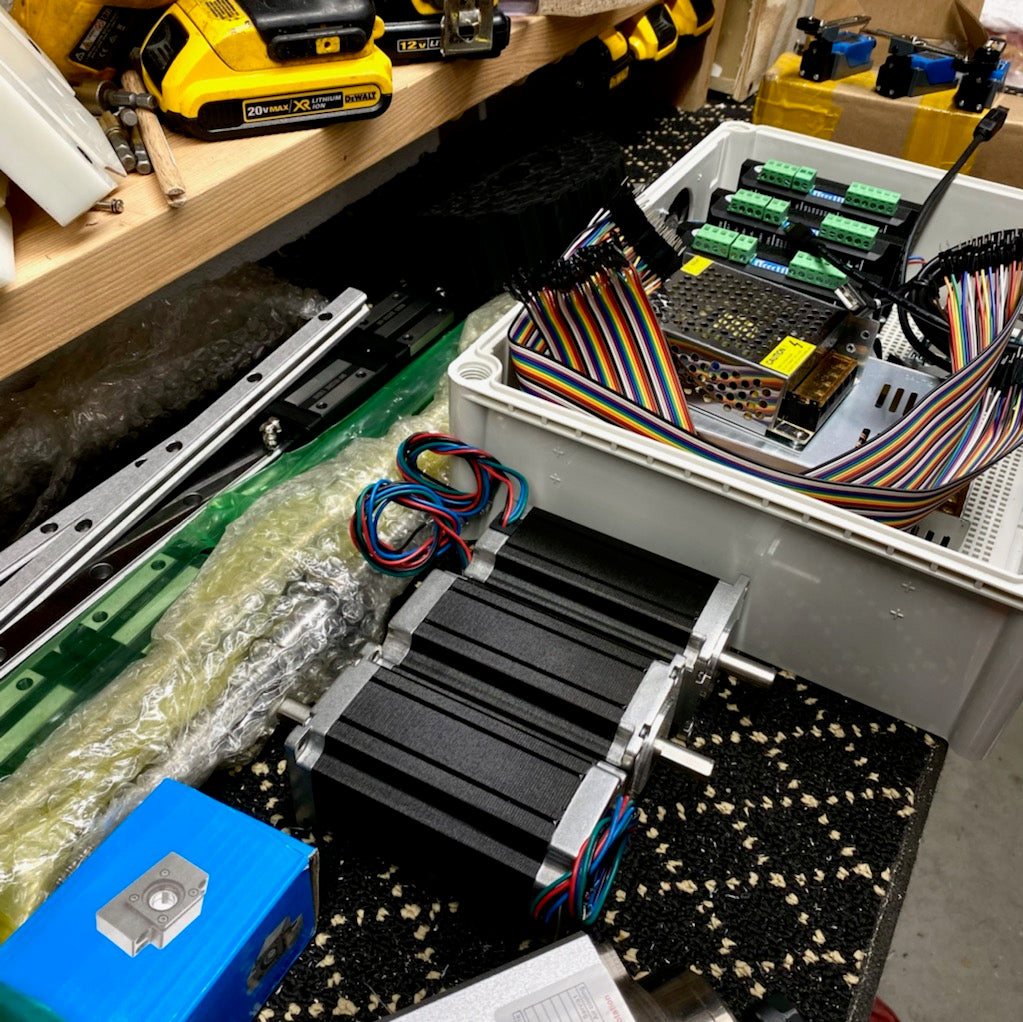

So basically, to start off the process of acquiring our first cnc machine we've decided to custom build our own. Basically, the overall idea was to build a cnc that would suite our needs and to provide one basic function: cut out molds and attempt to save money doing it. Our process started in Autocad Fusion360, to construct the blueprints for the cnc machine and tweak and virtually fit components together. We want to achieve a rock solid machine, so we have chosen the path of epoxy granite which in our case will be primarily comprised of sand and epoxy mixture with some concrete dye for coloring.

The solidarity of the epoxy granite should provide us with less unnecessary movement within the machine to be able to provide a consistent and accurate tool cutting paths for a better finished product. Due to the pandemic, shipping times for certain parts for the machine have hindered our ability to get it constructed and operational however it is still in progress regardless. We'd like to see this machine come to fruition within the next 1-2 months after testing has been completed before implementing it full time into our process.

This will truly be the future of LOA and it's "no off the shelf molds" approach to a 100% custom product and unique in our own creativity. Utilizing the cnc will provide our end users with a manufacturer like consistency between any two products with the customer relationship of a small time business owner.