Kydex: An Introduction

Share

What is Kydex?

Kydex is a tough thermoplastic acrylic-polyvinyl chloride initially developed in the 1960s, and is typically manufactured and shipped in "sheets". These sheets can then be heated up with a high-degree heat to make the Kydex sheet pliable, and then placed over a pre-existing mold and vacuum-formed to a high degree of definition. This level of definition helps define the retention offered by each holster, thus these holsters typically only accommodate one specific gun. There are many benefits to using Kydex over other materials for holsters and knife sheaths, including toughness and scratch-resistance. Kydex rates a Rockwell “R” hardness rating of 90.

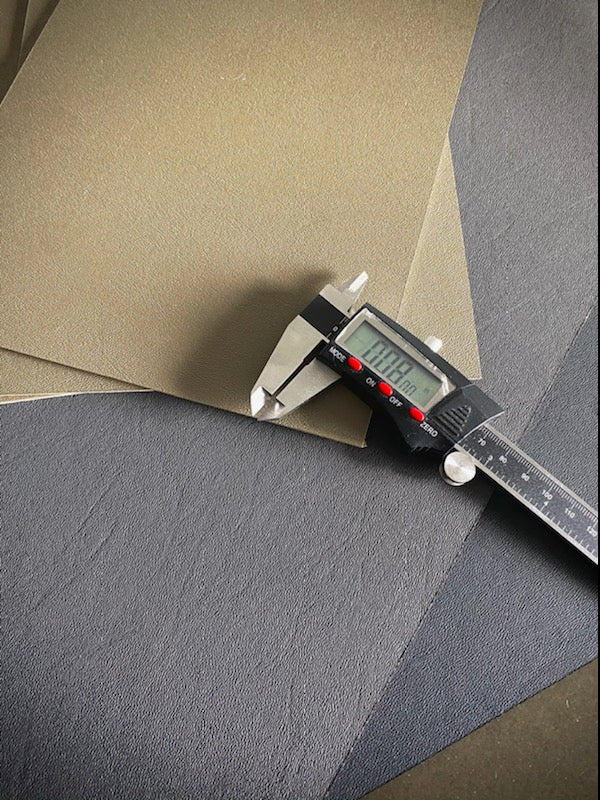

Kydex sheets come in a variety of thicknesses. The popular thicknesses are 0.060", 0.080", 0.093", and 0.125". These thicknesses define the level of detail and retention, as well as the durability. 0.060" will often offer the greatest definition, while being the least durable. This trend heads in the opposite direction as the thickness increases. Here at LOA, we prefer our IWB (Inside-The-Waistband) holsters with a thickness of 0.080". This ensures we achieve good detail and retention while also having an appropriate amount of "flex", which is necessary for comfort while carrying. We also prefer our OWB (Outside-The-Waistband) holsters to have a thickness of 0.125". This ensures the holster has the maximum durability while being used roughly in the field.